飞秒高速热反射测量(FSTR)是一种泵-探针光热技术,使用超快激光加热样品,然后测量其在数ns内的温度响应。泵浦(加热)脉冲在一定频率的范围内进行调制,这不仅可以控制热量进入样品的深度,还可以使用锁定放大器提取具有更高信噪比的表面温度响应。

展示全部

从4000年前,印度开采以来,金刚石在人类历史上一直扮演着比其他材料引人注意的角色,几个世纪以来,诚勿论加之其因稀缺而作为财富和声望象征属性。单就一系列非凡的物理特性,例如:

已知较硬的材料,在室温下具有较高的热导率,宽的透光范围,较坚硬的材料,可压缩性较小,并且对大多数物质是化学惰性,就足以使得其备受推崇,所以金刚石常常被有时被称为“终ji工程材料”也不那么为人惊讶了。

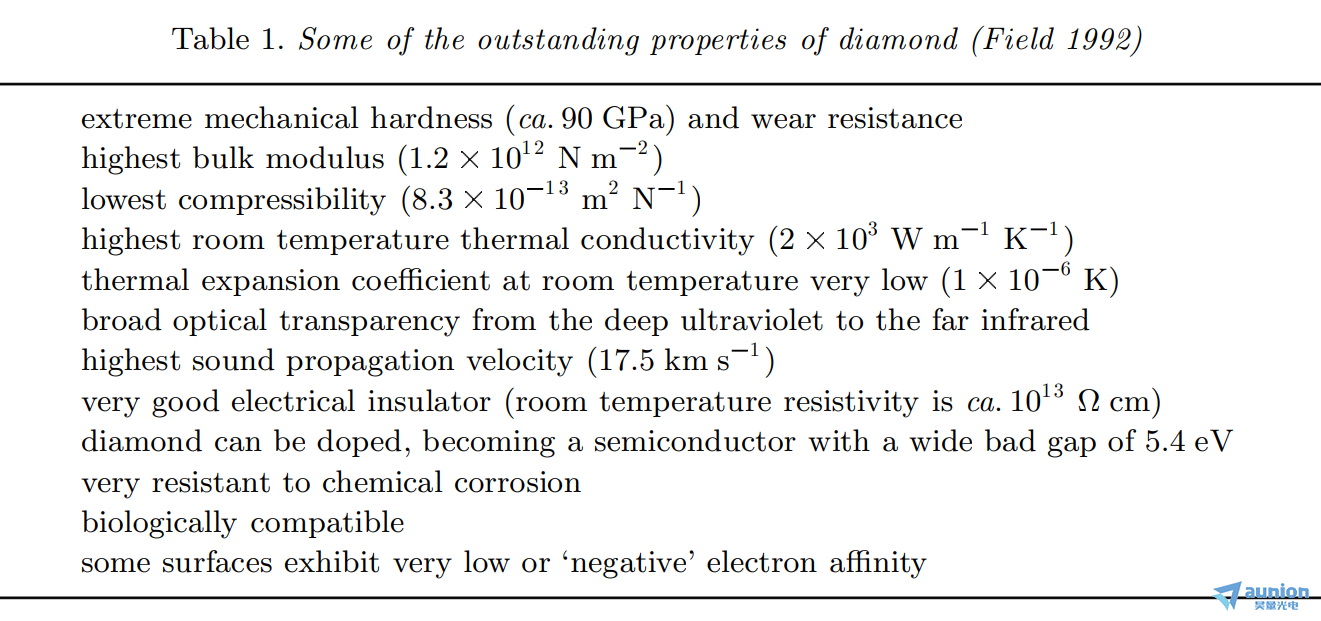

一些金刚石的物理特性

但是因为大型天然钻石的成本和稀缺性,金刚石的工业化应用一致非常困难。200 年前,人们就知道钻石是仅由碳组成(Tennant 1797),并且进行了许多尝试以人工合成金刚石,作为金刚石在自然界中常见的同素异构体之一的石墨,被尝试用于人造金刚石合成。

虽然结果确被证明其过程是非常困难

因为石墨和金刚石虽然标准焓仅相差 2.9 kJ mol-1 (Bundy 1980),但因为一个大的活化势垒将两相隔开,阻止了石墨和金刚石在室温和大气下相互转化。

有趣的是,这种使金刚石如此稀有的巨大能量屏障也是金刚石之所以成为金刚石的原因。

但是终究在1992年,一项称之为HPHT(high-pressure high-temperature)生长技术的出现,并随着通用电气发布为几十年来一直用于生产工业金刚石的标准技术。

在这个过程中,石墨在液压机中被压缩到数万个大气压,在合适的金属催化剂存在下加热到 2000 K 以上,直到金刚石结晶。由此产生的金刚石晶体用于广泛的工业过程,利用金刚石的硬度和耐磨性能,例如切割和加工机械部件,以及用于光学的抛光和研磨。

高温高压法的缺点是它只能生产出纳米级到毫米级的单晶金刚石,这限制了它的应用范围。

直到金刚石的化学气相沉积(CVD)生产方法以及金刚石薄膜的出现,该金刚石的形式可以允许其更多的高ji特性被利用。

相比起HPHT 复制自然界金刚石产生的环境和方法,化学气相沉积选择将碳原子一次一个地添加到初始模板中,从而产生四面体键合碳网络结果。

化学气相沉法,顾名思义,其主要涉及在固体表面上方发生的气相化学反应,从而导致沉积到该表面上。

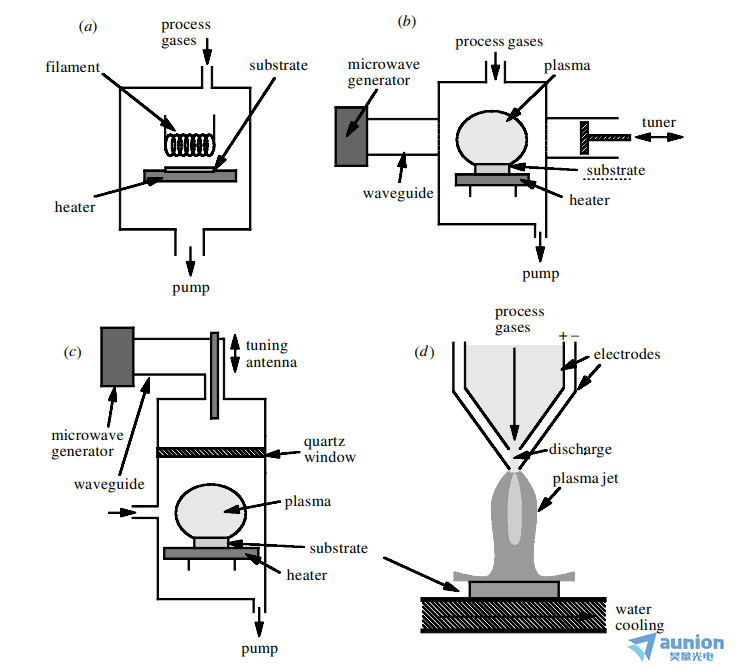

下图展示了一些比较常见的制备方法

一旦单个金刚石微晶在表面成核,就会在三个维度上进行生长,直到晶体聚结。而形成了连续的薄膜后,生长方向就会会限定会向上生长。

因此得到的薄膜是具有许多晶界和缺陷的多晶产品,并呈现出从衬底向上延伸的柱状结构。

不过,随着薄膜变厚,晶体尺寸增加,而缺陷和晶界的数量减少。这意味着较厚薄膜的外层通常比初始形核层的质量要好得多。

下文中会提到的在金刚石薄膜用作热管理散热器件时,通常将薄膜与其基材分离,底部的 50-100 um 是通过机械抛光去除。尽管如此,在 CVD 过程中获得的金刚石薄膜的表面形态主要取决于各种工艺条件,导致其性能表现个不一致,相差很大。这也为作为散热应用中的一些参数测量,例如热导率等带来了很大挑战。

金刚石薄膜在作为散热热管理材料应用时,有着不错的前景,与此同时也伴随着巨大挑战。

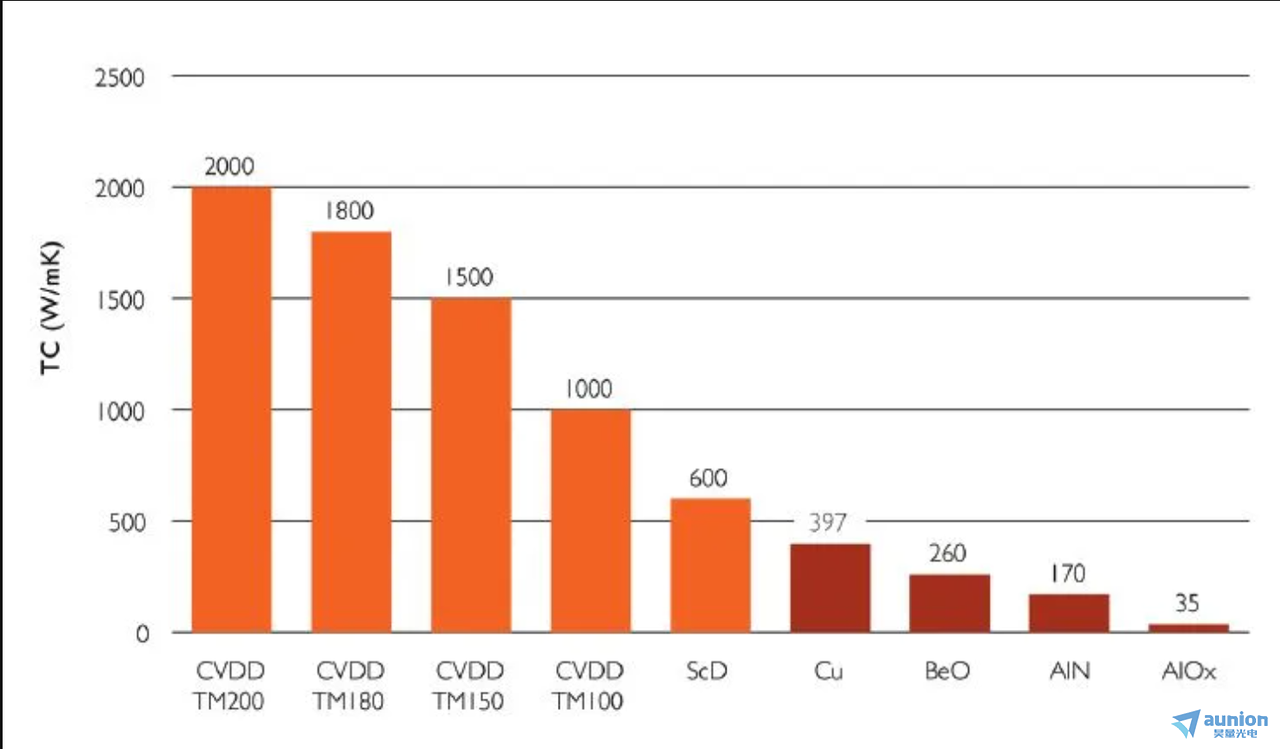

一方面,而在热学方面,金刚石具有目前所知的天然物质中Z高的热导率(1000~2000W/(m·K )),比碳化硅(SiC)大4倍,比硅(Si)大13倍,比砷化稼(GaAs)大43倍,是铜和银的4~5倍,目前金刚石热沉片大有可为。

下图展示了常见材料和金刚石材料的热导率参数:

另一方面,但人造金刚石薄膜的性能表现,往往远远低于这一高水平。

并且就日常表现而言,现代大功率电子和光电器件(5G应用,半导体芯片散热等)由于在小面积内产生大量热量而面临严重的冷却问题。为了快速制冷,往往需要一些高导热性材料制成的散热片/散热涂层发热端和冷却端(散热器,风扇,热沉等等)

CVD 金刚石在很宽的温度范围内具有远优于铜的导热率,而且它还具电绝缘的优势。

早在1996年沃纳等人就在可以使用导热率约为 2 W mm-1 K-1 的大面积 CVD 金刚石板用于各种热管理应用。 包括用于集成电路的基板(Boudreaux 1995),用于高功率激光二极管的散热器(Troy 1992),甚至作为多芯片模块的基板材料(Lu 1993)。从而使得器件更高的速度运行,因为设备可以更紧密地安置而不会过热。 并且设备可靠性也有望提高,因为对于给定的器件,安装在金刚石上时合流合度会更低。

比起现在流行的石墨烯,金刚石也有着其独特优势。

金刚石薄膜的热导率表征不是一个简单的问题,特别是在膜层厚度很薄的情况下

美国国防部研究计划局(DARPA)的电子热管理金刚石薄膜热传输项目曾经将将来自五所大学的研究人员聚集在一起,全面描述CVD金刚石薄膜的热传输和材料特性,以便更好地进一步改善热传输特性,可见其在应用端处理优化之挑战。

而这其中,用于特殊需求材料热导率测量的飞秒高速热反射测量(FSTR)(又叫飞秒时域热反射(TDTR)测试系统)发挥了较重要的作用,它在精确测量通常具有高表面粗糙度的微米厚各向异性薄膜的热导率的研究,以及在某些情况下,CVD金刚石薄膜的热导率和热边界改善研究,使其对大功率电子器件的热管理应用根据吸引力的研究上发挥了决定性指导作用。

常见的材料热学测试方法,包括闪光法(Laser Flash),3-Ω法,稳态四探针法,悬浮电加热法,拉曼热成像法,时域热反射法(TDTR)等。

而对于CVD金刚石薄膜的热学测量,受限于在过程中可能需要多层解析、精细的空间分辨率、高精度分析,以及解析薄膜特性和界面的能力,飞秒高速热反射测量(FSTR)(又叫飞秒时域热反射(TDTR)测试系统)已成为为过去十年来普遍采用的的热导率测量方法之一。

飞秒高速热反射测量(FSTR),也被称为飞秒时域热反射(TDTR)测量,被用于测量0.1 W/m-K至1000 W/m-K,甚至更到以上范围内的热导率

系统适用于各种样品测量,如聚合物薄膜、超晶格、石墨烯界面、液体等。

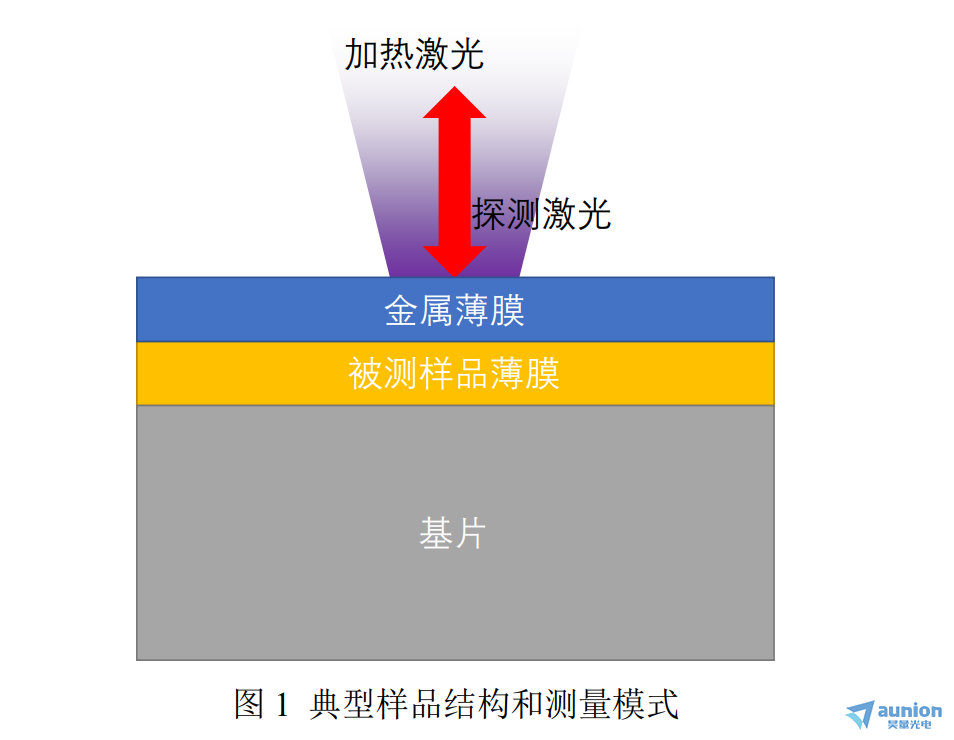

总的来说,飞秒高速热反射测量(FSTR)是一种泵-探针光热技术,使用超快激光加热样品,然后测量其在数ns内的温度响应。泵浦(加热)脉冲在一定频率的范围内进行调制,这不仅可以控制热量进入样品的深度,还可以使用锁定放大器提取具有更高信噪比的表面温度响应。

探测光(温度感应)脉冲通过一个机械级,该机械级可以在0.1到数ns的范围内延迟探头相对于泵脉冲的到达,从而获取温度衰减曲线。

如上文提到,因为生长特性,导致典型的金刚石样品是粗糙的、不均匀的和不同厚度特性的

这就为飞秒高速热反射测量(FSTR)的CVD 金刚石薄膜热学测量带来了一些挑战。

具体而言,粗糙表面会影响通过反射而来的探测光采集,且过于粗糙导致实际面型为非平面,这对理论热学传递建模分析也会引入额外误差,在某些情况下,可以对样品进行抛光以降低表面粗糙度,但仍必须处理薄膜的不均匀和各向性质差异。

对于各向异性材料,存在 2D 和 3D 各向异性的精确解析解,但这使得热导率和热边界电阻的确定更加困难,并且具有额外的未知属性。

即使样品中和传导层铝模之间总是存在未知的边界热阻,但是通常使用单个调制频率可以从样本中提取两个未知属性,这意味着在大多数情况下测量可以提取层热导率。

然而,对于金刚石样品,样品内纵向和横向热导率是不同的,这意味着需要额外的测量来提取这两种特性;这可以通过改变一些系统参数来实现校正,参见系统参数描述(详情联系请上海昊量光电)。

另一个困难是确定金刚石 CVD 的热容量,根据生长质量和样品中存在的非金刚石碳(NDC)的数量,生长出来的金刚石的热容量值相差较大。在这种情况下对于<5 um的金刚石薄膜,测量将完全穿透金刚石样品,抵达样品到下面的基底材料

(上图不同情况下的金刚石薄膜TDTR测量分析手段将会有很大不同)

这使得测量对金刚石-基底边界电阻也很敏感。这意味着测量可能总共有五个未知参数:1)铝膜-金刚石间边界热阻,2)金刚石内横向热导率,3)金刚石内纵向热导率,4)金刚石热容量,5)金刚石-基底材料间边界热阻

即使结合一定分析处理手段,见设备说明(详情联系请上海昊量光电),准确提取所有未知参数也很困难。

确认 测量相对于样本尺寸的采样量很重要;飞秒高速热反射测量(FSTR)通常是基于标准体材料传热建模,而现在一些测量的块体材料样品越来越小,对于高质量的单晶半导体,基于块体材料的传热模型分析假设是有效的,但是对于更多缺陷和异质材料,例如 CVD 金刚石,这个假设就只是一个近似值。

通常而言,金刚石生长过程中,颗粒梯度会非常大,这也可能会导致热导率梯度非常大。

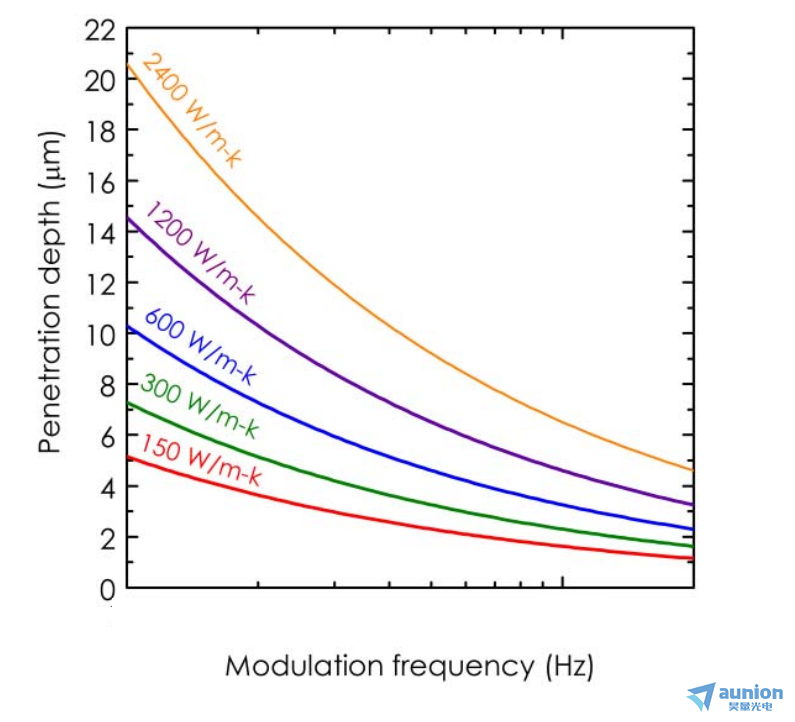

此外,非金刚石碳(NDC,non-diamond carbon)含量、晶粒尺寸或表面粗糙度的局部变化也可能影响热导率的局部测量。TDTR测量中,可以 通过控制调制频率,从而实现加热深度控制,从而实现采样深度控制(详细技术讨论联系请上海昊量光电)

对于不同热导率样品和不同加热频率,测量薄膜中采样 可能从1-2 um 到 20 um 不等 (相对应的,薄膜厚度超过300微米)

更多 挑战和技术细节,受限于篇幅,将在后续更新继续讨论,如您有兴趣就相关设备和技术问题进行交流,可联系上海昊量光电获取更多信息。

关于昊量光电:

上海昊量光电设备有限公司是目前国内知名光电产品专业代理商,也是近年来发展迅速的光电产品代理企业。除了拥有一批专业技术销售工程师之外,还有拥有一支强大技术支持队伍。我们的技术支持团队可以为客户提供完整的设备安装,培训,硬件开发,软件开发,系统集成等工作。秉承诚信、高效、创新、共赢的核心价值观,昊量光电坚持以诚信为基石,凭借高效的运营机制和勇于创新的探索精神为我们的客户与与合作伙伴不断创造价值,实现各方共赢!

您可以通过我们昊量光电的官方网站www.auniontech.com了解更多的产品信息,或直接来电咨询4006-888-532。