在位椭偏仪测试装置可分为两类,一类是把设计的装置直接和椭偏仪的两个臂连接,另外就是把设计好的装置放置在两臂之间,不改变椭偏仪原始的任何设计。后者设计使用更方便简洁,有利于装置的更换。

展示全部

椭偏仪在位表征电化学沉积的系统搭建(七)- 当前在位监测装置设计

3当前在位监测装置设计

3.1真空镀膜系统集成

在位椭偏仪测试装置可分为两类,一类是把设计的装置直接和椭偏仪的两个臂连接,另外就是把设计好的装置放置在两臂之间,不改变椭偏仪原始的任何设计。后者设计使用更方便简洁,有利于装置的更换。如图1-12所示,是报道过的椭偏仪在位测试的装置图。

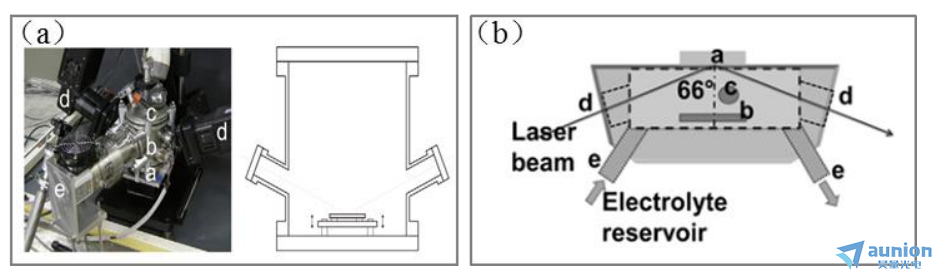

图1-12(a)是M.Magnozzi等设计一个实时在位光谱椭偏测量的高真装置。该装置是基于一个圆柱型管,在其两端有两个KF100法兰(见图1-12(a),左)。底部为KF100法兰(a)作为支撑样品的支架,安装有加热器和两个双动电偶;主体(b)容纳几个焊接在适当角度的法兰,用于椭偏测量、电气连接和泵送;顶部的KF100法兰(c),易于拆卸进入内室;主机四个法兰,可根据需要容纳真空计、气体进口和薄膜沉积来源。因此,通过改变附在法兰上的元件(窗、进气口、源),就有可能改变腔室的应用(不同入射角的椭偏测量、可控气氛、不同薄膜沉积)。腔室的横截面如图1-12(a)右所示。由于三对法兰配备了熔融硅窗,所以可以进行66°、70°和90°入射角下的椭圆偏振测量。该腔体的设计可以安装在WoollamM2000旋转补偿椭圆计d的臂上,无需对仪器进行任何修改,本仪器的设计原则上与任何水平安装的椭偏仪兼容。

图1-12(b)是Alexandre Zimmer等人设计的基于旋转补偿的椭偏仪的耦合流池,它直接安装在测角仪上,可以实现实时采集椭偏数据和电化学数据。耦合流池,由聚醚醚酮(PEEK)制成,包括两个石英窗口,允许椭圆光束垂直经过并到达工作电极表面再反射垂直经过出去,其中椭偏光束的入射角是66°。流动池(约40毫升),包含一个面对工作板的铂栅对电极和一个KCl饱和甘汞参比电极。电池中电解液的更新是由两个泵(型号323E,Watson Marlow)连接进、出口的管道实现。该装置的优点是垂直经过石英窗口,zui大程度上减小了光在传播途中的损耗,但是它的不足之处在于只可以在一个特定入角度(66°)下进行椭偏测量。

图1-12(a)椭偏仪在位监测真空沉镀膜腔体:左图为实验装置照片,腔体(a、c下、上法兰,b主腔体)插入M2000椭圆计的臂d中。前景中放置的是涡轮分子泵e;右图为高真空室的截面;(b)电化学阳极化的三电极配置的耦合流池图[18]:a、b、c、d、e分别为工作电极间、对电极、参比电极、石英窗和电解液进、出口

3.2液流腔体(flow cell)

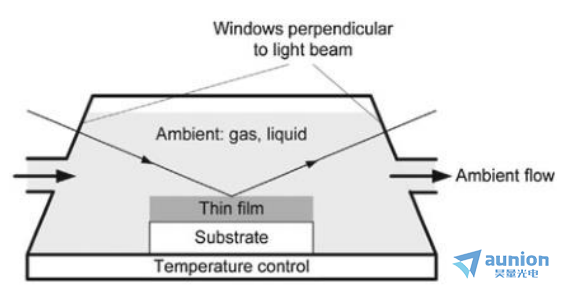

zui常用液流腔体电解池的结构是图1-13所示的梯形室(从侧面看),通常池体由提供流体进出的两个口及实现光的入射与出射的两个观察窗口组成。流体体可为液体、蒸汽或气体,由外部泵或气体流量控制器注入池体。观察窗口需要根据入射角的不同而改变,所以在设计池体之前要考虑使用样本的布鲁斯特角度或伪布鲁斯特角度来决定特定的入射角,以此提高信号灵敏度。

图1-13流动型池体侧视图

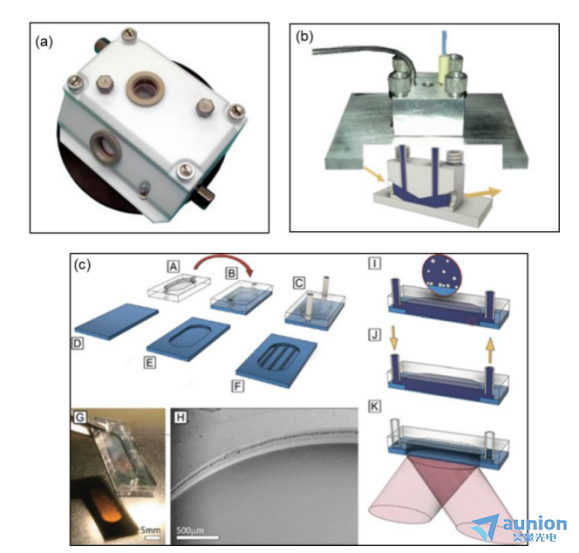

图1-14(a)是文献中用制作使用的池体实物图,可以看到其观察窗口位于短边侧面,液体进出口位于长边侧面。文中用该池体在200ms的时间分辨率和400nm波长下监测C12E5的平衡吸附。图1-14(b)是另外一篇文献中报道的常规硅晶圆上进行参考测试的常流池实物图和侧面示意图,可以看到液体的进出从池体的顶端实现,观察窗口位于侧面,入射角固定为75°。图1-14(c)是在(b)中常规流池的基础上进行改进的池体设计及制作过程图,整体形状和(b)一样,液流进出也是在上面。不同的是把不透明的池体改为透明材料,池体更小,且监测窗口在池体下方。

图1-14(a)流动池体实物图;(b)用于在固定的75°入射角的硅晶圆上进行参考测试的常流池实物图和侧面示意图;(c)中[A-F]基于膜结构的密封腔室的制造,以及带有薄膜的组装流池硅膜,[G]和[H]显示池体和膜的边缘,[I−K]基于半透明膜的椭偏仪测试流体设计示意图

了解更多椭偏仪详情,请访问上海昊量光电的官方网页:

https://www.auniontech.com/three-level-56.html

更多详情请联系昊量光电/欢迎直接联系昊量光电

关于昊量光电:

上海昊量光电设备有限公司是光电产品专业代理商,产品包括各类激光器、光电调制器、光学测量设备、光学元件等,涉及应用涵盖了材料加工、光通讯、生物医疗、科学研究、国防、量子光学、生物显微、物联传感、激光制造等;可为客户提供完整的设备安装,培训,硬件开发,软件开发,系统集成等服务。

您可以通过我们昊量光电的官方网站www.auniontech.com了解更多的产品信息,或直接来电咨询4006-888-532。

相关文献:

[1] WONG H S P, FRANK D J, SOLOMON P M et al. Nanoscale cmos[J]. Proceedings of the IEEE, 1999, 87(4): 537-570.

[2] LOSURDO M, HINGERL K. ellipsometry at the nanoscale[M]. Springer Heidelberg New York Dordrecht London. 2013.

[3] DYRE J C. Universal low-temperature ac conductivity of macroscopically disordered nonmetals[J]. Physical Review B, 1993, 48(17): 12511-12526. DOI:10.1103/PhysRevB.48.12511.

[4] CHEN S, KÜHNE P, STANISHEV V et al. On the anomalous optical conductivity dISPersion of electrically conducting polymers: Ultra-wide spectral range ellipsometry combined with a Drude-Lorentz model[J]. Journal of Materials Chemistry C, 2019, 7(15): 4350-4362.

[5] 陈篮,周岩. 膜厚度测量的椭偏仪法原理分析[J]. 大学物理实验, 1999, 12(3): 10-13.

[6] ZAPIEN J A, COLLINS R W, MESSIER R. Multichannel ellipsometer for real time spectroscopy of thin film deposition from 1.5 to 6.5 eV[J]. Review of Scientific Instruments, 2000, 71(9): 3451-3460.

[7] DULTSEV F N, KOLOSOVSKY E A. Application of ellipsometry to control the plasmachemical synthesis of thin TiONx layers[J]. Advances in Condensed Matter Physics, 2015, 2015: 1-8.

[8] DULTSEV F N, KOLOSOVSKY E A. Application of ellipsometry to control the plasmachemical synthesis of thin TiONx layers[J]. Advances in Condensed Matter Physics, 2015, 2015: 1-8.

[9] YUAN M, YUAN L, HU Z et al. In Situ Spectroscopic Ellipsometry for Thermochromic CsPbI3 Phase Evolution Portfolio[J]. Journal of Physical Chemistry C, 2020, 124(14): 8008-8014.

[10] 焦杨景.椭偏仪在位表征电化学沉积的系统搭建.云南大学说是论文,2022.

[11] CANEPA M, MAIDECCHI G, TOCCAFONDI C et al. Spectroscopic ellipsometry of self assembLED monolayers: Interface effects. the case of phenyl selenide SAMs on gold[J]. Physical Chemistry Chemical Physics, 2013, 15(27): 11559-11565. DOI:10.1039/c3cp51304a.

[12] FUJIWARA H, KONDO M, MATSUDA A. Interface-layer formation in microcrystalline Si:H growth on ZnO substrates studied by real-time spectroscopic ellipsometry and infrared spectroscopy[J]. Journal of Applied Physics, 2003, 93(5): 2400-2409.

[13] FUJIWARA H, TOYOSHIMA Y, KONDO M et al. Interface-layer formation mechanism in (formula presented) thin-film growth studied by real-time spectroscopic ellipsometry and infrared spectroscopy[J]. Physical Review B - Condensed Matter and Materials Physics, 1999, 60(19): 13598-13604.

[14] LEE W K, KO J S. Kinetic model for the simulation of hen egg white lysozyme adsorption at solid/water interface[J]. Korean Journal of Chemical Engineering, 2003, 20(3): 549-553.

[15] STAMATAKI K, PAPADAKIS V, EVEREST M A et al. Monitoring adsorption and sedimentation using evanescent-wave cavity ringdown ellipsometry[J]. Applied Optics, 2013, 52(5): 1086-1093.

[16] VIEGAS D, FERNANDES E, QUEIRÓS R et al. Adapting Bobbert-Vlieger model to spectroscopic ellipsometry of gold nanoparticles with bio-organic shells[J]. Biomedical Optics Express, 2017, 8(8): 3538.

[17] ARWIN H. Application of ellipsometry techniques to biological materials[J]. Thin Solid Films, 2011, 519(9): 2589-2592.

[18] ZIMMER A, VEYS-RENAUX D, BROCH L et al. In situ spectroelectrochemical ellipsometry using super continuum white laser: Study of the anodization of magnesium alloy [J]. Journal of Vacuum Science & Technology B, 2019, 37(6): 062911.

[19] ZANGOOIE S, BJORKLUND R, ARWIN H. Water Interaction with Thermally Oxidized Porous Silicon Layers[J]. Journal of The Electrochemical Society, 1997, 144(11): 4027-4035.

[20] KYUNG Y B, LEE S, OH H et al. Determination of the optical functions of various liquids by rotating compensator multichannel spectroscopic ellipsometry[J]. Bulletin of the Korean Chemical Society, 2005, 26(6): 947-951.

[21] OGIEGLO W, VAN DER WERF H, TEMPELMAN K et al. Erratum to ― n-Hexane induced swelling of thin PDMS films under non-equilibrium nanofiltration permeation conditions, resolved by spectroscopic ellipsometry‖ [J. Membr. Sci. 431 (2013), 233-243][J]. Journal of Membrane Science, 2013, 437: 312..

[22] BROCH L, JOHANN L, STEIN N et al. Real time in situ ellipsometric and gravimetric monitoring for electrochemistry experiments[J]. Review of Scientific Instruments, 2007, 78(6).

[23] BISIO F, PRATO M, BARBORINI E et al. Interaction of alkanethiols with nanoporous cluster-assembled Au films[J]. Langmuir, 2011, 27(13): 8371-8376.

[24] 李广立. 氧化亚铜薄膜的制备及其光电性能研究[D]. 西南交通大学, 2016.

[25] 董金矿. 氧化亚铜薄膜的制备及其光催化性能的研究[D]. 安徽建筑大学, 2014.

[26] 张桢. 氧化亚铜薄膜的电化学制备及其光催化和光电性能的研究[D]. 上海交通大学材料科 学与工程学院, 2013.

[27] DISSERTATION M. Cellulose Derivative and Lanthanide Complex Thin Film Cellulose Derivative and Lanthanide Complex Thin Film[J]. 2017.

[28] NIE J, YU X, HU D et al. Preparation and Properties of Cu2O/TiO2 heterojunction Nanocomposite for Rhodamine B Degradation under visible light[J]. ChemistrySelect, 2020, 5(27): 8118-8128.

[29] STRASSER P, GLIECH M, KUEHL S et al. Electrochemical processes on solid shaped nanoparticles with defined facets[J]. Chemical Society Reviews, 2018, 47(3): 715-735.

[30] XU Z, CHEN Y, ZHANG Z et al. Progress of research on underpotential deposition——I. Theory of underpotential deposition[J]. Wuli Huaxue Xuebao/ Acta Physico - Chimica Sinica, 2015, 31(7): 1219-1230.

[31] PANGAROV n. Thermodynamics of electrochemical phase formation and underpotential metal deposition[J]. Electrochimica Acta, 1983, 28(6): 763-775.

[32] KAYASTH S. ELECTRODEPOSITION STUDIES OF RARE EARTHS[J]. Methods in Geochemistry and Geophysics, 1972, 6(C): 5-13.

[33] KONDO T, TAKAKUSAGI S, UOSAKI K. Stability of underpotentially deposited Ag layers on a Au(1 1 1) surface studied by surface X-ray scattering[J]. Electrochemistry Communications, 2009, 11(4): 804-807.

[34] GASPAROTTO L H S, BORISENKO N, BOCCHI N et al. In situ STM investigation of the lithium underpotential deposition on Au(111) in the air- and water-stable ionic liquid 1-butyl-1-methylpyrrolidinium bis(trifluoromethylsulfonyl)amide[J]. Physical Chemistry Chemical Physics, 2009, 11(47): 11140-11145.

[35] SARABIA F J, CLIMENT V, FELIU J M. Underpotential deposition of Nickel on platinum single crystal electrodes[J]. Journal of Electroanalytical Chemistry, 2018, 819(V): 391-400.

[36] BARD A J, FAULKNER L R, SWAIN E et al. Fundamentals and Applications[M]. John Wiley & Sons, Inc, 2001.

[37] SCHWEINER F, MAIN J, FELDMAIER M et al. Impact of the valence band structure of Cu2O on excitonic spectra[J]. Physical Review B, 2016, 93(19): 1-16.

[38] XIONG L, HUANG S, YANG X et al. P-Type and n-type Cu2O semiconductor thin films: Controllable preparation by simple solvothermal method and photoelectrochemical properties[J]. Electrochimica Acta, 2011, 56(6): 2735-2739.

[39] KAZIMIERCZUK T, FRÖHLICH D, SCHEEL S et al. Giant Rydberg excitons in the copper oxide Cu2O[J]. Nature, 2014, 514(7522): 343-347.

[40] RAEBIGER H, LANY S, ZUNGER A. Origins of the p-type nature and cation deficiency in Cu2 O and related materials[J]. Physical Review B - Condensed Matter and Materials Physics, 2007, 76(4): 1-5.

[41] 舒云. Cu2O薄膜的电化学制备及其光电化学性能的研究[D]. 云南大学物理与天文学院,2019.

展示全部